Monitor Mounts 2-axis hinges for folding tables Calculation tool for Friction Hinges

FRICTION HINGES (CONSTANT TORQUE HINGES)

Friction hinges (constant torque hinges, positioning hinges) are pure mechanical components, used to hold an object in the desired position. Typical applications are monitors in laptop and industrial applications, special suitcases, office equipment, safety equipments, lids, doors, arms, seat rests, etc.

The working principle is based on friction between input and output shaft; that's why position hinges are also called friction hinges; to generate the desired torque an according number of clips is put on the shaft. Precision clips and shaft components, a proprietary lubricant, and a proprietary manufacturing process form the basis for Reell’s technology for providing consistent torque over life. Torque increments are achieved through the addition of clips and allow custom torque specifications with standard components. Standard torque tolerance over life is a maximum of +/-15% with zinc and +/- 20% with insert plastic molded parts.

One of the main qualitiy aspects of friction hinges is the difference between static and dynamic torque. Clip technology allows a close and predictable relationship between static and dynamic torque, and specification of higher torques without compromising torque tolerance or life. The breakaway torque in our hinges is really close to the dynamic torque which provides a convinient jerkfree movement - and due to "Reell's Torque Engine" with clip technology the torque remains consistent over life.

The main features of our friction hinges:

- constant torque over whole angular range

- extremely small volume

- no backlash (only small spring back after taking back the driving torque)

- designed for indoor applications (for outdoor applications special corrosion protection required)

- high lifetimes

- custom designs possible

The mounting area requires special consideration because our friction hinges provide high torque in a small package. Therefore the mounting must be able to support the high forces and torques without being distorted or suffer from material fatigue.

Positioning hinges are available for external mounting or torque insterts for integration into the rotating axis. Additional versions include VESA-Monitor-Mounts and spherical joints with swivel function used as a tablet holder or for lighting applications . With 60 degrees free movement in all directions perfect for stabilizing tablets and lights in the right position!

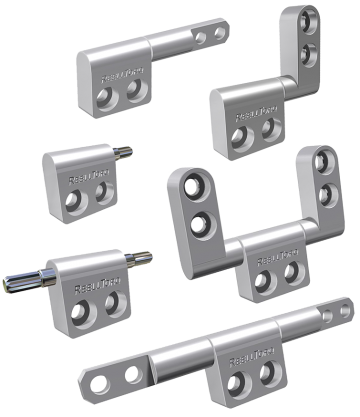

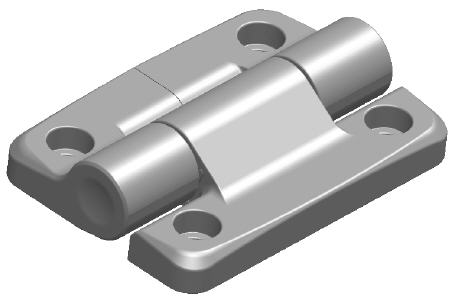

FRCITION HINGES FOR EXTERNAL MOUNTING (RT / PHx / MHx)

The constant torque hinges on this page are suited for mount to a customer mechanics.

Special care has to be taken in the mounting area. The friction hinges provide a lot of torque in a small package which has to be supported by a fairly small mounting area. So this area has to be designed in a way that the torque can be supported without distortion or material breakage due to fatigue.

- various models

- equal torque in either direction standard

- PHK, PH35, MH15 and MH18 with optionally reduced torque in one direction

- NEW: friction hinges in stainless steel (PHCS) and Aluminum (PHCA)

| name | image | setting angle | torque Nm |

information |

RT050 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 0.11 0.23 0.34 |

- up to 50,000 cycles - torque +/-30% - clip technology |

RT070 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

360° | 0.34 0.45 0.56 0.68 0.79 0.90 |

- up to 50,000 cycles - torque +/-20% - clip technology |

|

RT100 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

360° | 0.90 1.36 1.81 2.26 |

- up to 50,000 cycles - torque +/-20% - clip technology |

|

RT120 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

360° | 2.26 3.39 4.52 5.65 |

- up to 50,000 cycles - torque +/-20% - clip technology |

|

PHT drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 2.0 / 0.5 4.0 / 0.5 6.0 / 0.5 |

- up to 10,000 cycles - torque +/-20% - clip technology - differing torque for each direction |

PHA (8mm) drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 0.28 0.37 0.46 0.55 0.65 |

- up to 25,000 cycles - torque +/-15% - spring back < 1° - clip technology |

| PHK left, straight  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)right, straight  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)dual, straight  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)left, angled 90°  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)right, angled 90°  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)dual, angled 90°  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 1.5 2.5 3.5 4.5 5.0 5.5 |

- up to 20,000 cycles - torque +/-20% - spring back < 1° - clip technology |

| PHB* left, straight holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)right, straight holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)dual, straight holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)left, countersunk holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)right, countersunk holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)dual, countersunk holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 0.44 0.78 1.22 1.57 2.01 2.35 2.79 |

- up to 20,000 cycles - torque +/-20% - spring back < 1° - clip technology |

| PHC* straight holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)countersunk holes  drawing 2D (pdf)

drawing 2D (pdf) drawing (igs)

drawing (igs) |

|

270° | 0.4 0.8 1.2 1.6 2.0 2.4 2.8 |

- up to 20,000 cycles - torque +/-20% - spring back < 1° - clip technology |

| aluminium version of the PHC! PHCA straight holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 0.4 0.8 1.2 1.6 2.0 2.4 2.8 |

- material: aluminum - up to 50,000 cycles - torque +/-20% - spring back < 1° - clip technology |

| stainless steel version of the PHC! PHCS straight holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs)countersunk holes  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 0.4 0.8 1.2 1.6 2.0 2.4 2.8 |

- material: 316 stainless steel - up to 20,000 cycles - torque +/-20% - spring back < 1° - clip technology |

PHL* drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 0.9 1.4 1.8 2.3 2.8 3.4 |

- up to 20,000 cycles - torque +/-20% - spring back < 1° - clip technology |

PH35* drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 5.65 / 1.13 6.78 / 1.13 7.91 / 1.13 9.04 / 1.13 10.17 / 1.13 11.30 / 1.13 |

- up to 20,000 cycles - torque +/-10% - spring back < 1° - clip technology; - one direction with reduced torque |

MH10** drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 1.5 / 0.94 2.5 / 1.56 3.5 / 2.19 |

- up to 20,000 cycles - torque +/-10% - spring back < 1° - clip technology; - one direction with reduced torque |

MH12** drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 0.4 0.8 1.2 1.6 |

- up to 10,000 cycles - torque +/-20% - spring back < 1° - clip technology; |

MH13** drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 1.0 2.0 3.0 |

- up to 25,000 cycles - torque +/-10% - spring back < 1° - clip technology; |

MH14 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 1.4 1.8 2.2 2.6 3.0 3.4 3.8 4.2 4.6** 5.0** 5.4** 5.8 |

- up to 10,000 cycles - torque +/-20% - spring back < 1° - clip technology; - ** only on request |

MH15 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 2.0 / 1.25 3.0 / 1.88 4.0 / 2.50 5.0 / 3.13 6.0 / 3.75 7.0 / 4.38 8.0 / 5.00 |

- up to 20,000 cycles - torque +/-10% - spring back < 1° - clip technologiy; - balanced or one direction with reduced torque |

MH18 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

270° | 4.0 / 1.8 6.0 / 1.8 8.0 / 1.8 |

- up to 20,000 cycles - torque +/-25% - spring back < 1° - clip technology; - one direction with reduced torque |

**: these finishes are available: black (in higher quantities special colors)

marked in bold verions are available as sample / in lower quantities (for versions with different colors / holes not all designs)

FRICTION HINGES AS TORQUE INSERTS (TI)

The constant torque hinges on this page are prepared to be integrated into the rotating axis which means they become integral part of the customer mechanics.

Special care has to be taken in the mounting area. The friction hinges provide a lot of torque in a small package which has to be supported by a fairly small mounting area. So this area has to be designed in a way that the torque can be supported without distortion or material breakage due to fatigue.

- 5 models

- torque range from 0.2Nm to 8Nm per hinge

- two torque levels for TI200 series (one direction 65% of the other)

| name | image | setting angle | torque Nm |

information |

| TI-C5M 84002-xxx  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 0.15 0.25 0.30 |

- up to 30,000 cycles - torque +/-25 ... +/-30% - spring back < 1° - clip technology |

| TI-120-X.XX - XX (former MH20-0yy) 20-0yy  drawing 2D (pdf)

drawing 2D (pdf) one fin, drawing 3D (igs)

one fin, drawing 3D (igs) two fins, drawing 3D (igs)

two fins, drawing 3D (igs) |

|

360° | 0.25 0.35 0.50 0.65 0.80 1.00 1.20 |

- up to 25,000 cycles - torque +/-20 ... +/-45% - spring back < 1° - clip technology |

TI-130-X.XX-X - XX drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (step)

drawing 3D (step) |

|

360° | 1.0 1.5 2.0 |

- up to 25,000 cycles - torque +/- 0.3/0.4 Nm of dynamic torque - clip technology |

| TI-140-X.XX - XX (former MH40-0yy) 40-xyy  drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 1.4 1.8 2.2 2.6 3.0 3.4 3.8 4.2 |

- up to 25,000 cycles - torque +/-20 ... +/-30% - spring back < 1° - clip technology |

TI-150-X.XX-X - XX drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (step)

drawing 3D (step) |

|

360° | 2.0 3.0 4.0 |

- up to 25,000 cycles - static torque +/-10% of dynamic torque - spring back < 1° - clip technology |

TI-160-X.XX-X - XX drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (step)

drawing 3D (step) |

|

360° | 4.0 5.0 6.0 |

- up to 25,000 cycles - static torque +/-10% of dynamic torque - spring back < 1° - clip technology |

| TI-220-X.X 7-0yy  drawing 2D (pdf)

drawing 2D (pdf) mounting manual (pdf)

mounting manual (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | CCW / CW 1.5 / 0.94 2.0 / 1.25 2.5 / 1.56 3.0 / 1.88 3.5 / 2.19 |

- up to 10,000 cycles - torque +/-12 ... +/-26% - spring back < 1° - clip technology - one directional with reduced torque |

| TI-240-X.X 80146-0yy  drawing 2D (pdf)

drawing 2D (pdf) mounting manual (pdf)

mounting manual (pdf) drawing 3D (igs)

drawing 3D (igs)yy = torque in Nm x 10 |

|

360° | CCW / CW 4.0 / 2.50 5.0 / 3.13 6.0 / 3.75 7.0 / 4.38 8.0 / 5.00 |

- up to 20,000 cycles - torque +/-12 ... +/-20% - spring back < 1° - clip technology - one directional with reduced torque |

| TI-320-X.XX-XX 83560-XXX  drawing 2D (pdf)

drawing 2D (pdf) installation guide (pdf)

installation guide (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 0.50 0.75 1.0 1.25 1.5 |

- up to 50,000 cycles - torque +/-20% - spring back < 1° - clip technology |

| TI-330-X.XX-XX 83xxx-XXX  drawing 2D (pdf)

drawing 2D (pdf) installation guide (pdf)

installation guide (pdf) drawing 3D (step) -01 knurled shaft

drawing 3D (step) -01 knurled shaft drawing 3D (step) -02 knurled adapter

drawing 3D (step) -02 knurled adapter |

360° | 1.0 1.5 2.0 2.5 |

- up to 50,000 cycles - torque +/-20% - spring back < 1° - clip technology |

|

| TI-340-X.XX-XX 83560-XXX  drawing 2D (pdf)

drawing 2D (pdf) installation guide (pdf)

installation guide (pdf) drawing 3D (step)

drawing 3D (step) |

360° | 2.0 3.0 4.0 5.0 |

- up to 25,000 cycles - torque +/-20%(25%) - spring back < 1° - clip technology |

|

| TI-360-X.XX-XX 83560-XXX  drawing 2D (pdf)

drawing 2D (pdf) installation guide (pdf)

installation guide (pdf) drawing 3D (step)

drawing 3D (step) |

360° | 6.0 8.0 10.0 |

- up to 25,000 cycles - torque +/-20% - spring back < 1° - clip technology |

Stainless Steel Friction Hinges and Monitor Mounts for Medical Applications

The collection of data sheets on various hinges and monitor mounts in this section focuses on stainless steel solutions, such as those required in medical technology.

In addition to torque hinges without or with constant torque, friction hinges with different torque per direction (also one-way) and friction hinges with adjustable torque (adjustable friction) can also be found here. Torque hinges with a hollow shaft are a special design that is well suited as a bearing for rotating elements with cable feed-through, e.g. as a monitor holder. Torque hinges are even available for clean room applications).

- many different designs with different functionality

- made of stainless steel

- suitable for medical applications

- optional torque hinges for cleanroom applications

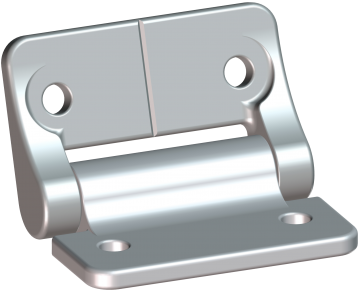

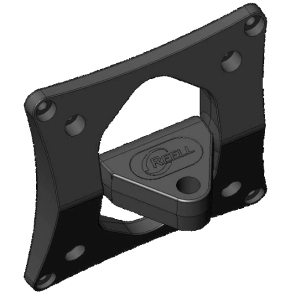

Monitor Mounts

We offer Monitor Mounts from two of our manufatuers. On the one hand friction hinges as vesa monitor mount (vTilt) or as spherical joint (SI), or Hollow shaft firction hinge (HTH60) of our supplier Reell. On the other hand the monitor holders KA-TLG of our partner Sugatsune, which are available as one-axis and two-axis versions.

On the subject of monitor mounts, our manufacturer Reell Precision now offers a hollow shaft friction hinge: the HTH60 Hollow Shaft Friction Hinge; like all Reell friction hinges, the HTH60 Hollow Shaft Friction Hinge features compactness, durability and good haptic experience. The Reell HTH60 Hollow Shaft Friction Hinge provides designers with an easy-to-install hollow torque hub that allows wire (and other media tubes) feed-through to electronic equipment and monitors. The HTH60 can rotate 360° and attaches to any surface from one side. The large 18mm inner diameter allows cables, hoses and connectors to pass through to monitors and other electrical equipment within the axis of rotation, keeping cables out of sight and protected, and simplifying the overall assembly process. Applications for the HTH60 Hollow Shaft Friction Hinge can be found wherever cables or other media hoses need to be routed from a stationary system to a moving end piece via one or more joints, such as in lighting systems (e.g., surgical lights), medical systems (e.g. dental chairs), laboratory equipment, and even robotic joints.

| name | image | setting angle | torque Nm |

information |

vTilt** drawing 2D (pdf)

drawing 2D (pdf) mounting manual (pdf)

mounting manual (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

360° | 3.0 / 1.88 4.0 / 2.5 5.0 / 3.13 6.0 / 3.75 8.0 / 5.0 5.0 / 0.9 6.0 / 0.9 7.0 / 0.9 8.0 / 0.9 |

- up to 10,000 cycles - torque +/-20%(25%) / +/-30%(35%) - clip technology - one direction with reduced torque |

vMX drawing 2D (pdf)

drawing 2D (pdf) installation guide (pdf)

installation guide (pdf)3D-model coming soon |

|

60°x90° | 5.0, 7.0 | - up to 50,000 cycles - symmetrical torque - black or white - monitor weight up to 9.5kg (21lbs) |

SJ-200 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

Rotation 360° 60° horizontal/vertical |

0.2 0.4 |

- up to 50,000 cycles - torque +/-30% |

SJ-300 drawing 2D (pdf)

drawing 2D (pdf) Zeichnung 2D Monting Plate (pdf)

Zeichnung 2D Monting Plate (pdf) drawing 3D (igs)

drawing 3D (igs) |

|

Rotation 360° 60° horizontal/vertical |

1.0 / 0.6 2.0 / 1.4 |

- up to 50,000 cycles - torque +/-30% |

SJ-500 drawing 2D (pdf)

drawing 2D (pdf) drawing 3D (step)

drawing 3D (step) |

|

Rotation 360° 60° horizontal/vertical |

4.0 / 6.0 / 8.0 | - up to 50,000 cycles - torque +/-30% |

KA-TLG drawing 2D (pdf)

drawing 2D (pdf) |

|

210° / 360° | 15 | -available as one- or

two-axis version |

HTH60 drawing 2D (pdf)

drawing 2D (pdf) |

|

360° | 5.5 7.0 8.5 10.0, 11.5 |

-25.000 cycles - 60 x 27mm -hollow shaft 18mm |

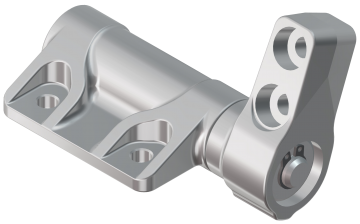

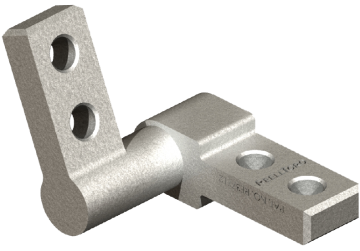

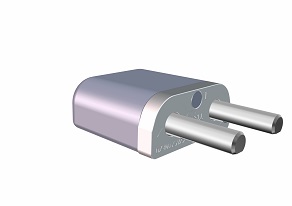

2-axis friction hinges for tray tables and panel positioning

The DX100 positioning hinge of our supplier Reell Precision Manufacturing features a unique dual-axis design that allows for full fold-over performance in panels as thin as 8mm - thinner than traditional bifold or articulating hinges. This enables tables and panels to fold and stow in narrower spaces, allowing for mor compact designs with less weight. The DX100 friction hinge is ideal for airline and vehicle meal trays or fold-away work surfaces in applications such as medical carts and equipment.

The DX100 friction hinge uses Reell's ReellTorq™ technology that provides long life, premium feel motion that holds solidly in any position along its full range of motion, rotation without rattle or position creep.

The DX100 positioning hinge is available with two torque profiles:

• An equal torque profile with either 0.5 N-m, 1.0 N-m, or 1.5 N-m of holding force around both axes.

• A mixed torque profile with 0.5 N-m around one axis and 1.5 N-m around the other. This allows for sequencing in motion as the panel folds. The lower torque axis will rotate first, followed by the second axis after a stop is reached on the first axis.

PRINT PAGE |

PRINT PAGE |