ELECTRIC ACTUATORS

Actronic consists of two parts - the actuator and the drive and control electronics. Our actuators basically are the integration of a motor into a mechanical subsystem, so that it can be mounted and used in the overall system.

An actuator could be the combination of a standard motor with an attached mechanical transmission (e.g. gearbox, lead screw, linear table, ...) or a completely integrated system consisting of a motor and some further mechanical parts. Also the selection of the technology needs some consideration with respect to the application, both from the technical point of view (how it works, what is required life, which space is available, any thermal or environmental constraints), but also regarding costs - in many applications a simple on/off type actuator like a solenoid is sufficient, other applications require a servo control actuator with some mechanical transmission, other applications ask for a direct drive technology like a voice-coil-actuator.

We offer a variety of actuators in combination with mechanical options. We are happy to help you with the selection or with the modifcation of our standard parts or the development of completely new designs:

- Voice-Coil-Actuators: Voice-Coil-Motors are single phase mostly linear motors which work according the Lorentz-force-principle; they are suited for very high dynamic applications with fairly short stroke up to a few millimeters, e.g. as valve actuator, especially in ventilator applications or for short stroke dynamic positioning in semiconductor indstustry; they are available also with an optional guidance (sliding bearing or roller bearing) and encoder.

- Moving-Coil-Actuators: Moving-Coil-Actuators are ready to use linear actuators or even linear/rotary actuators with a linear ball bearing and encoder; the actuator used could be a voice-coil-motor for short strokes or a 3-phase linear motor for longer strokes; applications can be found in semi conductor industry, packaging, botteling and test applications.

- Moving-Magnet-Actuators: servotube actuators are shaft motors and moving-magnet-actuators, which means the moving part is the magnet assembly; the disadvantage of course is the higher weight compared to the coil, but there are no moving cables which is an advantage regarding robustness; the integrated sliding bearing and the use of the magnets for position measurement makes them a cost effective solution for a direct drive linear actuator; typical applications can be found in packaging applications and assembly and handling machines; they can be combined to x-y-systems or portal- or multiaxis systems.

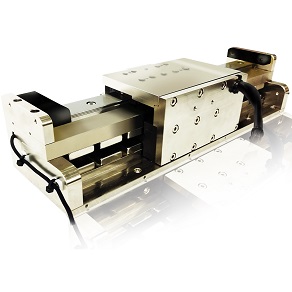

- linear motor tables: linear motor axes are ready to use linear systems with a linear motor, a linear guideance and an encoder feedback. Also available as miniature xyteta positioning systems for alignment processes, e.g. in semiconductor manufacturing.

- lead screw / ball screw / roller screw servo actuators and tables: basically this is the integration of a screw and a motor; this can be electrical cylinders or rodless linear actuators / tables. There almost no limits of options. If the motor is connected via a flange you have the highest flexibilty for your motor choice: widings for 12V, 24V, 230V or 400V, all feedback types (Encoder, Resolver, absolut encoder (EnDat, Hiperface DSL, BiSS) and connectors, brakes, etc.; electrical cylinders with integrated motor feature less components, ease of use and better life. We offer types with lead srew, ball crew and roller screw. For applications in food, beverage or pharmaceutical industries with very hygienic demands we offer FDA certified stainless steel and foodgrade electrical cylinders with IP66, IP67 or IP69K!

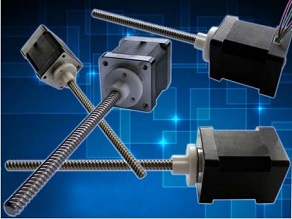

- stepper motor lead screw actuators: for these actuators the shaft is used directly as the lead screw for easy integration in the customer application, e.g. in medical, diagnostics, semiconductor and optical applications

- linear solenoids: solenoids are primarily on/off type actuators - depending on the application solenoids can be optimised for high force and short stroke (push/pull solenoids) or longer stroke and less force (tubular solenoids) or cost (open frame type solenoids), but there are special versions like the proportional solenoids or the so called super-stroke-solenoids which allow for a proportional control.

- rotary solenoids: also rotary solenoids typically are on/off type actuators; in our design the rotary movement is achieved by conversion of a little linear movement by 3 helical ball races into a rotary movement; the active move is only uni-directional, the return move needs an external force, e.g. an optional spring; depending on size there are angles of 25°, 35°, 45°, 67.5° or 95° available; various winding options allow the adaptation for various voltages and duty cycles; applications can be found in semiconductor, as optical or laser shutter, as diverter gates in sorting mechanisms, as stopping mechanisms in handlind and transportationsystems etc..

- bistable rotary solenoids: bistable rotary solenoids use a permanent magnet and can actively be switched in either direction (bidirectional; only a short pulse is necessary to switch from one endposition to other; this allows for a high overcurrent and therefore high switching torque resulting in a fast response time; the smallest size is 7mm diameter only, used e.g. as shutter in optical or thermal cameras; bigger sizes up to 60mm diameter use industrial type bearings can be found in sorting applications, e.g. for bank notes, mail sorting or deposit bottle sorting etc.

- vibration actuators: vibration actuators are available as components (coil assembly and magnet assembly) or with spring bearing; typical supply voltages are 12V or 24V. They are well suited for medical or lab and diagnostics application like mixinig or separation of fluids; custom versions possible.

PRINT PAGE |

PRINT PAGE |