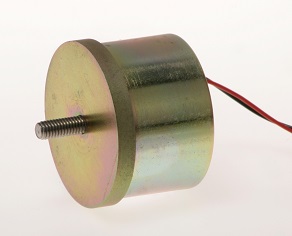

ELECTROMAGNETS / ELECTRIC HOLDING MAGNETS (EM)

Electromagnets or electric holding magnets develop their high attraction force towards magnetic materials when they are energized. The applications are manifold - wherever ferrous parts have to be fixed during processing or assembly, or ferrous parts have to be attracted or transported. However, electromagnets are most commonly used as holding mechanisms for fire doors or other safety devices.

Since the field decreases very strongly even at a small distance, the emphasis in production of electric holding magnets is on very good flatness and an extremely thin coating is chosen. This also applies to the optionally available armature plates.

The following basic properties can be specified for the electric holding magnets of the EM series:

- five sizes with 25mm, 32mm, 40mm, 50mm and 80mm diameter

- holding force up to 2100N (powered on in stop position)

- high holding force at low power

- standard windings for 12Vdc or 24Vdc

- flexible cable outlet to the side or to the rear

Options for the electric holding magnets:

- ejector Pin: preloaded spring pin to overcome residual magnetism, reduces holding force by approx. 10%

- custom windings for series requirements

- further sizes for series production

- armature plate (soft iron, nickel-plated) as magnetic counterpart

*warm = constant temperature, achieved in calm air by nominal voltage.

After switching off, a residual magnetism of approx. 5% of the Nominal holding force maintained.

| type | AP27 | AP34 | AP42 | AP52 | AP82 |

| diameter (+/-0.2mm) | 27mm | 34mm | 42mm | 52mm | 82mm |

| h | 4mm | 5mm | 5mm | 6mm | 8mm |

| threaded bolt | M4 x P0.7mm | M4 x P0.7mm | M6 x P1.0mm | M6 x P1.0mm | M8 x P1.25mm |

| total height (+/- 1.2mm) | 18mm | 18mm | 20mm | 20mm | 25mm |

HOLDING MAGNETS WITH ELECTRIC RELEASE (HMER)

Holding magnets with permanent magnets permanently develop a high attraction force against magnetic materials which are brought into their immediate vicinity by the permanent magnet. In addition, however, they have an electric coil with which the field of the permanent magnet can be neutralised, i.e. switched off, when the correct voltage is applied.

Like all electric holding magnets, they are used to fix ferrous parts during machining or assembly, to attract and transport ferrous parts.

At present, we do not offer a standard HMER series; examples of manufactured components:

- HMER0040-24: holding force >200N, 24Vdc supply voltage, dimensions d= 40mm, h = 27mm

- HMER4928-12: holding force >600N, 12Vdc supply voltage, dimensions d= 49mm, h = 28mm

HIGH POWER HOLDING MAGNETS (SMPD)

Like the electric holding magnets, the permanent magnet-based holding magnets also develop a high attraction force towards magnetic materials - but without current and cannot be switched off. Like electric holding magnets, holding magnets are used to fix ferrous parts, e.g. during assembly processes or on the pin board. Our holding magnets use strong magnetic materials and are therefore characterised by a high force density.

| type | SMPD 00100 | SMPD 00101 | SMPD 00102 | SMPD 00103 | SMPD 00104 | SMPD 00163 | SMPD 00105 | SMPD 00164 |

| diameter (mm) | 6 | 8 | 10 | 13 | 16 | 20 | 25 | 32 |

| height (mm) | 20 | 20 | 20 | 20 | 20 | 25 | 35 | 40 |

| holding force (N) | 6 | 10 | 40 | 60 | 125 | 250 | 400 | 600 |

PDF Electromagnet Catalogue

PDF Electromagnet Catalogue

PRINT PAGE |

PRINT PAGE |