NEUGART GEARBOX FOR SERVO MOTORS

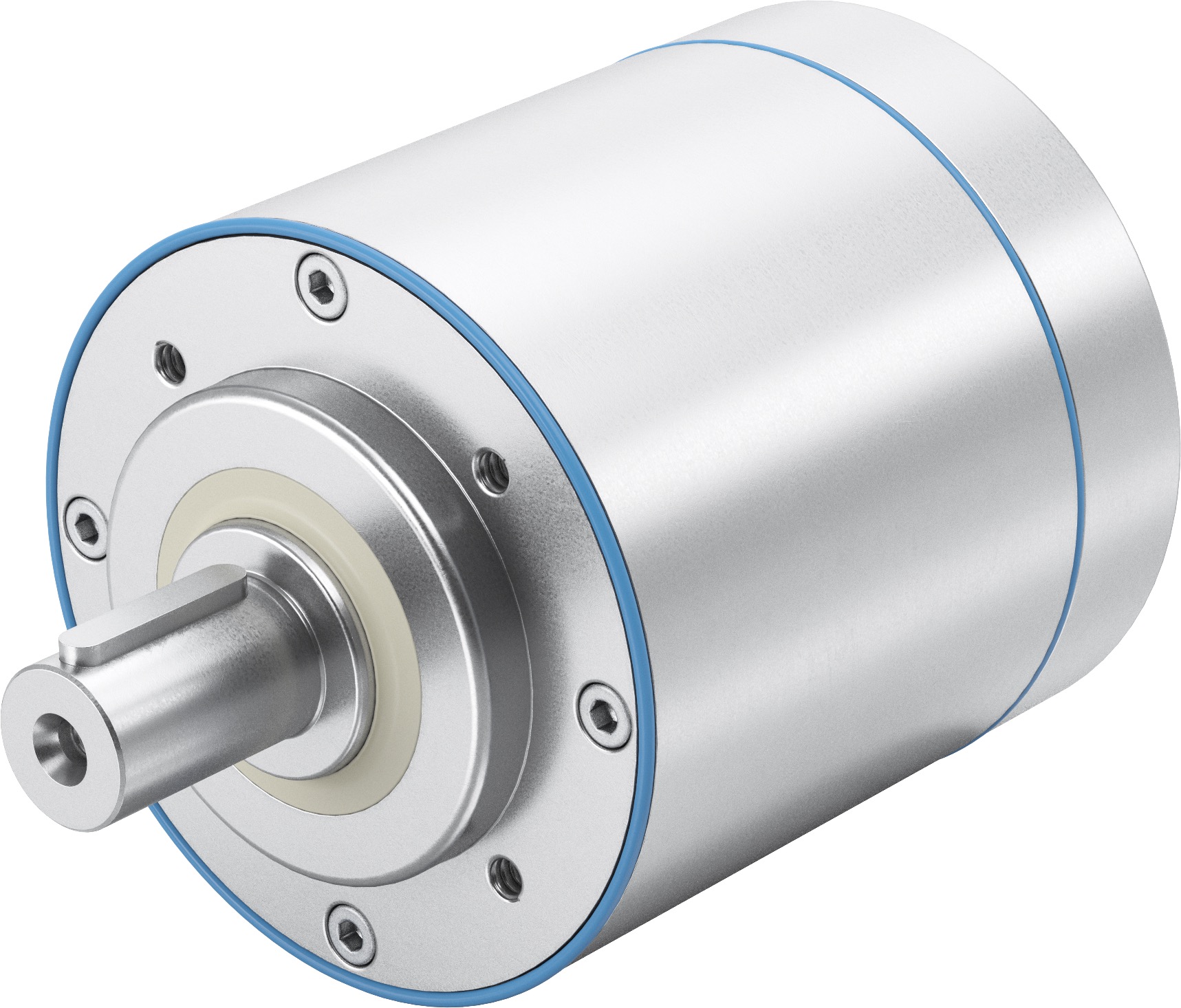

Planetary gearboxes are required for a wide range of electrical motion applications. Together with our manufacturer Neugart we offer various versions of servo gearboxes. Planetary gearboxes with output shaft are most frequently used.

Planetary gearboxes must be securely connected to the servo motor on the motor side (drive input side) and to the customer's mechanical system on the output side. For this purpose, the input flange of the planetary gearhead is individually adapted to the servo motor on the motor side by the manufacturer.

On the output side, various variants are available for the output shaft:

- output shaft with keyway for positive-fit and reliable power transmission

- smooth output shaft for a force-fit connection to a clutch (for highest torque transmissions also in reversing operation)

- Multi-tooth shaft according to DIN 5480 for toothed output shaft (e.g. for force-fit connection to a pinion with internal gearing)

The planetary gearbox units with output shaft are the ideal solution for many dynamic applications due to the low inertia of the rotating output shaft. The wide variety of planetary gearheads with output shaft gives you the maximum flexibility to select the right product for your application.

The most important features of planetary gearboxes with output shaft:

- flexibility through compact unit consisting of planetary gearbox with output shaft and servo motor

- flexibility through product variety with 1 to 3 gear stages, various reduction ratios, different toothings

- low inertia of the rotating output shaft

- suitable for dynamic applications

A special feature of Neugart is the option of purchasing the servo gearboxes directly with an assembled pinion tailored to your application. This means you receive a gearbox-pinion combination developed from a single source that guarantees the ideal technical match for your rack and pinion drive.

Another special feature at Neugart is the option of preparing the planetary gearbox directly for use in an industrial truck. The NGV series planetary gearboxes meet the special requirements of AGVs (AGVs) for compact design, high load capacity, high reliability and efficiency. In the NGV servo gearbox, specially developed wheels almost completely encase the gearbox. This means that the gearbox is basically located outside the vehicle in the wheel. This saves space. If the overall length of the drivetrain is to be reduced even further, the gearbox can also be mounted in what is known as direct engine mounting. In this case, the sun pinion is mounted directly on the motor shaft and the gearbox housing is bolted to the motor. This saves even more length by eliminating the motor adapter plate.

A wide variety of adapters make it possible to fit the NGV gearbox to almost any motor. Your advantage: You can use the optimum motors and control units for your application, because Neugart, as a pure gearbox manufacturer, offers its solutions independent of motors and control units from batch size 1. As Actronic Solutions, we can also offer you ready-made packages with servo motor and servo controller for low voltage, so that you can put your AGV into operation straight away:

- Servo Motors also for Low Voltage (12 Vdc / 24 Vdc / 48 Vdc): Servo Motors also for LowVoltage (12V/24V/48V)

- Servo Drives with DC-supply 12Vdc / 24Vdc / 48Vdc / 96Vdc / 180Vdc: Servo Drives Copley Argus / M-Series / IES / Accelnet Plus / Accenet and Kollmorgen AKD / AKD2G

The stainless steel servo gearboxes of the HLAE series from the manufacturer Neugart have been specially adapted to the requirements of the pharmaceutical industry and food technology. To prevent contamination, not only did the material have to be carefully selected, but the geometry of the gearbox also had to be designed in such a way that no dirt pockets or biofilms of germs and bacteria could form. The hygienic design of the HLAE gearbox has no dead spaces. Corners and edges are specially rounded to prevent build-up. The electropolished stainless steel surface and the special seals for IP69K protection also allow regular cleaning, even with aggressive cleaning substances.

The HLAE stainless steel servo gearboxes can be easily combined with our Kollmorgen hygienic servo motors and Tolomatic stainless steel lead screw linear actuators:

- Kollmorgen stainless steel servo motors in hygienic design with IP69K: stainless steel servo motors for hygienic applications

- Tolomatic stainless steel lead screw linear actuators: stainless steel lead screw linear actuators for hygienic applications

Variants for the servo gearboxes from the manufacturer Neugart (see also the information in the product overview in the pdf files):

- PLE: cost-effective planetary gearbox, maximum efficiency even at highest speeds

- PLQE: for high forces, low heat generation, easy to mount

- PLPE: extremely economical planetary gearbox due to best torque-low heat performance

- PLHE: new dimension in precision and economy

- PSBN: high-performance precision planetary gearbox with helical teeth for a particularly quiet drive

- PSN: helical-toothed precision planetary gearbox with low-noise synchronism for high bearing loads

- PLN: perfectly sealed straight-toothed planetary gearbox for best performance and high stiffness

- HLAE: Planetary gearbox made of stainless steel in hygienic design

- NGV: Planetary gearboxes for industrial AGVs (AGVs)

Rehfuss Modular planetary gearboxes PS

Through our new partner and manufacturer Rehfuss Drive Solutions GmbH, we can offer a versatile planetary gearhead. It promises combinability with different motor connections and a flange option for synchronous servo motors. The PS planetary gearhead is suitable for applications in a wide range of industries thanks to its long service life, high efficiency, modular design and freedom from maintenance, and is compatible with many gearhead manufacturers on the market on the gearhead output side.

The main features of PS planetary gearboxes:

- lifetime lubrication

- high input speeds

- whole numbered reduction ratios

- robust and compact

- high torsional stiffness

- aluminum housing

- universal mounting position

- axial load-free motor direct mounting by clamp connection

The main performance data of PS planetary gearboxes:

- torsional backlash: <7-<19 arcmin

- weight: approx. 0.4-12.8 kg

- efficiency at full load: 92-94%.

- service life: >30,000 h

- lubrication: lifetime lubrication

- protection class: IP54

- mounting position: universal

- permissible operating temperature: -20° to +90°

Rehfuss Hygienic planetary gearboxes PNH

With our new partner Rehfuss Drive Solutions GmbH, we were able to offer a manufacturer of planetary gear units especially for hygienic applications such as in the pharmaceutical industry, food industry or beverage industry. The gear units are characterized above all by the fact that they can be cleaned quickly, safely and efficiently and are corrosion-resistant as well as resistant to chemical cleaning agents and disinfectants. PNH planetary gear units also meet the specifications of the EHEDG (European Hygienic Engineering & Design Group) and have IP69K protection. We can offer a suitable total solution together with hygienic motors.

The main features of PNH planetary gearboxes:

- lubricant suitable for food industry (NFS H1 approved)

- robust and compact

- stainless steel housing (14404)

- universal mounting position

- whole numbered reduction ratios

- optimized sealing materials

- dead space free shaft seal

- safe motor-specific mounting system

- axial load-free motor direct mounting by clamp connection

The main performance data of PNH planetary gearboxes:

- torsional backlash: <7-12 arcmin

- efficiency at full load: 92-94%.

- service life: >30,000 h

- lubrication: H1 registered lifetime lubrication

- protection class: IP69K

- mounting position: universal

- permissible operating temperature: -25° to +90°

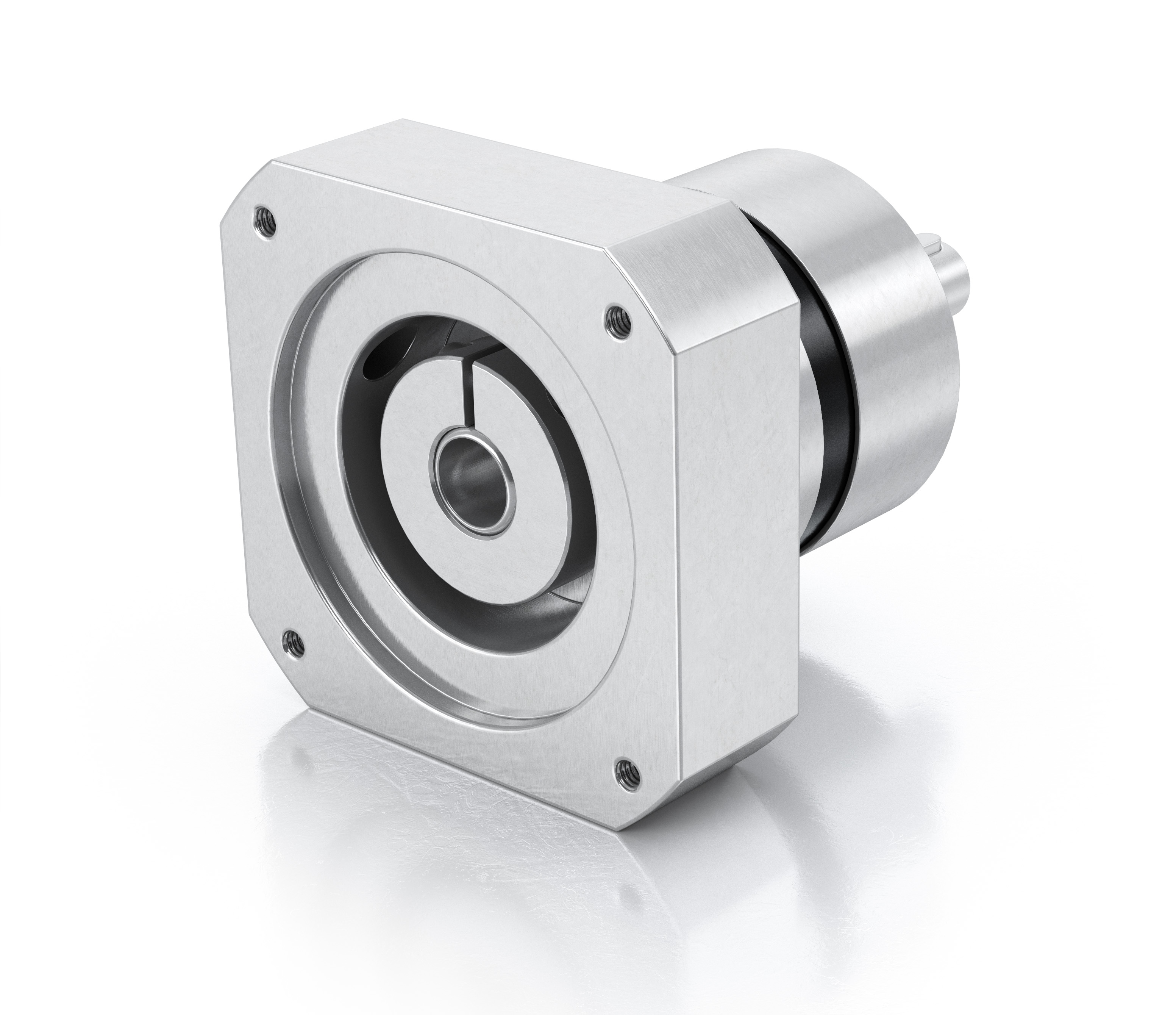

Rehfuss Bevel helical gearboxes KSN/KS

The helical bevel gearboxes from our new manufacturer Rehfuss Drive Solutions GmbH are designed as a compact drive unit for highly dynamic applications for operation with servomotors. Amply dimensioned bearings and gearing design ensure high operational reliability. The symmetrical inline housing can be universally installed or attached and guarantees maximum rigidity thanks to its integrated square flange on the output side. The KSN/KS bevel-helical gearboxes are available with solid or hollow shafts (with optional clamping set if required). The output shafts are also available in stainless steel.

The most important features of KSN/KS helical-bevel gearboxes:

- 4-edge flange with external centering

- Robust and compact

- High efficiency > 90%

- Single position universal

- Integer reduction ratios

- External screws made of stainless steel

- Smooth housing surface for particularly high surface quality requirements (hygienic drive, wash-down drive)

- Square flange for universal mounting options

- Symmetrical inline housing design enables mounting in all positions

- Maintenance-free and lifetime lubrication (> 30,000 h)

- Low backlash <6 arcmin

- H1 Lubricant for the food industry

- Modular motor flange system for adapting all common motors

- Protection class: IP65 (optional IP69K)

- Permissible operating temperature - 20°C to + 90°C

- Optional: Hollow shaft version with shrink disk

- Optional: Stainless steel cover to cover the hollow shaft

- optional: version with solid shaft

- Optional: Bevel helical gearbox in stainless steel

PDF Neugart Planetary Servo-Gearboxes Overview

PDF Neugart Planetary Servo-Gearboxes Overview

PRINT PAGE |

PRINT PAGE |