3-BALL ROTARY SOLENOIDS (R)

The standard rotary solenoid is an on/off type actuator, working with the reluctance principle which means the active move is uni-directional and an external force, e.g. a return spring, is needed to return to the starting position. The rotary movement in our 3-ball rotary solenoids is converted from a linear motion by the mechanical design of an inclined plane. There are three uniform spiral grooves that are stamped into both the case and the armature, called "ball races". The ball races provide the conversion of linear to rotary motion as well as the bearing system for the rotary movement.

The following properties have to be pointed out for our rotary solenoids:

- angle of rotation up to 95° (depending on type)

- starting torque up to 13Nm (gross starting torque at 20°C without return spring)

- high lifetime: up to >50 million cycles

- fast response time: switching times < 5ms possible (depending on size and load)

- mounting by threaded studs

- many options as standard: metric or SAE threads, shaft on either side, return spring, dust cover, tapped holes in armature plate

- reduced noise option by special dust cover

The efficiency of rotary on/off solenoids with return spring can be improved by using intelligent power electronics like Pick&Hold-Circuits.

the winding of the winding needs to match your application; at every size different options are available.

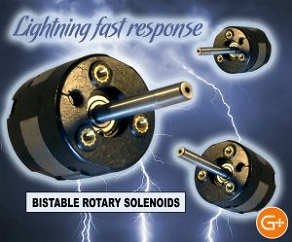

BISTABLE ROTARY SOLENOIDS (BRS)

Bistable Rotary Solenoids are rotary actuators which have been developed especially for shutter applications in laser or optical systems, diverter gates in paper transportation and sorting systems like e.g. banknote sorting mechanisms. They can be driven in either direction by a short electrical pulse and can hold in either end position with no power applied. Bistable Rotary solenoids use an internal permanent magnet and are bidirectional devices, reversing the voltage / current causes also a change of the direction of movement.

The most important properties of our bistable rotary solenoids:

- rotary angle up to +/-55° around center position

- no integral mechanical end stops (must be supplied either in the customer mechanics or as an custom option)

- torque up to 0.5Nm

- high lifetime due to ball bearings

- no axial travel

- fast response: cycle times < 5ms possible

- low temperature rise due to short pulses

- optional: viscous damping with ferro-fluids: smooth operation, soft mechanical end stop, less audible noise

PDF Rotary Solenoids Catalogue

PDF Rotary Solenoids Catalogue

PRINT PAGE |

PRINT PAGE |