VOICE COIL MOTORS (VCM) / VOICE COIL ACTUATORS

A Voice-Coil-Actuator is the technical use of the Lorentz-Force-Principle: the force of a current carrying wire in the magnetic field of a permanent magnet is proportional to the field strength and the current. A change of the direction of the current causes also the force to reverse; therefore voice coil motors are bidirectional actuators - both rotary and linear. Electrically the Voice-Coil-Motor (VCM) is a single phase motor and can be driven like a brushed DC-motor. A linear Voice-Coil-Actuator therefore is defacto a linear DC-motor for short stroke applications, a rotary Voice-Coil-Actuator is limited in its moving angle and therefore similar to a Limited Angle Torquer. Because of the comparably low moving mass Voice-Coil-Actuators are ideally suited for applications with high dynamic requirements and high frequency. Another substantial advantage of voice coil motors is the really small hysteresis. Altogether, voice coil motors are the ideal roatry or linear servo actuator for applications requiring short stroke (limited angle), good proportional control, bidirectional moves, high speed, good controllability for low noise and low shock, high efficiency and low hysteresis.

Benefits of our Voice Coil Actuators:

• proportional Control: variable position 1 to 100mm / up to 45°

• high Speed: vibration or marking

• high Efficiency: battery powered systems, backup systems, temperature sensitive media

• controllability: linear or rotary movement with low noise or low shock at mechanical endstop

• low Hysteresis: control systems with high repeatability

• high overload capability

In most cases Voice-Coil-Motors (VCMs) are manufactured as pure actuators; the control loop could be pressure, flow or position and there is no sensor in the actuator part. Some actuators include a sliding bearing for ease of use. Customers who would like to make the integration into their mechanical system on their own, therefore use the CVC series voice coil motors of our partner PBA or the VM series voice coil actuator with sliding bearing of our partners Geeplus.

For real positioning applications the voice coil motor gets integrated into a mechanical system with a linear guide like a cross roller bearing and an optical encoder - in this case the whole system, like CVCA series or RVCA series of PBA, becomes a linear motor axis or linear motor table for highly dynamic short stroke applications.

As other electrical motors also Voice Coil Motors (VCMs) develop a voltage while moving (Back-EMF), which is proportional to the relative velocity of the coil in the magnet assembly, so that at constant load and energisation a stationary speed would be achieved, if the stroke would be long enough (like in a DC brushed motor). Because the coil resistance changes with temperature constant force output can only be achieved by current control.

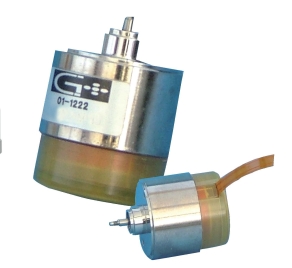

VOICE COIL ACTUATORS WITH SLIDING BEARING (VM)

The VM series Voice Coil Motors of our manufacturer Geeplus are designed as electric linear actuator components. The standard versions of these voice coil actuators are linear actuators and in the most applications the coil is the moving part; the VM series offers incorporate shafts and sliding bearing as standard to ensure accurate guidance of the coil assembly within the magnet assembly; position sensors are not included. Optionally the Voice Coil Actuators can be shipped without shaft and bearing and also completely customized versions in other sizes and even form factors are available (e.g. like short stroke U-shape ironless motors or rotary versions).

The VM series of Voice Coils Motors addresses applications where excellent control characteristics for short stroke bidirectional linear actuation is required, e.g. in medical or optical equipment. Voice Coil Actuators can develop force in either direction by reversing polarity of excitation. Very important is the very low hysteresis, which is typically two orders of magnitude less than in proportional solenoids. This and the flat force characteristic exhibited by voice coil actuators lend them to applications requiring precise control of force and / or position such as control valves, or lens and mirror positioning systems.

Our Junus servo amplifiers for DC-brushed motors are suitable as servo controllers for the VM voice coil actuators without feedback.

Electrical Termination of Voice Coil Actuators VM series

The connection to the moving coil of a voice coil motor must be implemented with care to ensure reliable operation. Flexible cable with many fine strands and Silicone Rubber insulation can provide reliable termination. Care should be taken that the leads are mechanically secured to the moving assembly preferably at some distance from the soldered joints (solder fuses the strands together, and leads to large stresses being applied to the termination pins, or to fatigue adjacent to the fuesed portion of the wire). The leads should be carefully routed to minimize stress. A more consistent means of termination is to use a flexible circuit. This is offered by our manufacturer Geeplus as standard in the VM2836, VM3334, VM4040, VM5050 and VM8080 devices (the electrical data are identical to the base versions VM2618, VM3322, VM4032, VM5042 and VM8054).

** coil configuration allows more stroke at less stroke

2-axis voice coil motors as tilting actuators for laser beam deflection

The VMXY80 dual-axis voice coil actuator from Geeplus provides rotational deflection about two axes and is designed for applications such as deflecting optical beams such as laser beams or light beams, and is ideally suited for data transmission between tall buildings or other structures that may be subject to movement.

The moving element provides frictionless rotation about the X and Y axes using a dual-axis flexbearing. The torque generation is provided by two pairs of coils and radially magnetized permanent magnets. As with all voice coil motors, the torque is proportional to the excitation current, resulting in independent deflection per axis depending on the driving current. A flexcircuit connection is incorporated tor a reliable electrical connection of the moving coils.

In principle, the VMXY voice coil drive concept is scalable and the manufacture of smaller or larger devices of similar design is possible, provided the quantities are economically viable. However, the 80 mm diameter device approaches the upper size limit for which radial magnets are available. Larger biaxial voice coil actuators can be made with segmented magnets, which in turn can be more easily made with a square footprint.

The current design VMXY80 shows a force of 0.8N at 100%ED on an OD fo about 70mm; the base is 80x80mm and height is 31mm. The coil mass is 3gr and the total assembly mass is 800gr.

VOICE COIL MOTORS WITH NO GUIDANCE (CVC)

The CVC series voice coil actuators of our manufacturer PBA don't incorporate a shaft or bearing system in form of a linear guide. The coil former is made of aluminium and offers threaded holes for mounting the coil to the external mechanics which needs to provide the guidance for the coil assembly. The leads are connected to the wire inside of the coil former and the gap is then filled with epoxy to provide a stable and reliable connection.

Our Junus servo amplifiers for DC-brushed motors are suitable as servo controllers for the CVC voice coil actuators without feedback.

- 13 sizes with 16 to 90mm diameter (bigger versions available on request!)

- continuous force range from 1N to 120N

- stroke from 5 to 40mm

- low electrical time constant

- zero cogging force

- no need for commutation, only 2 wires

- high reliabilty

| Voice Coils CVC-series | stroke (mm) |

peak force (N) |

continuous force (N) 100°C* |

peak current (A) |

continuous current (A) 100°C* |

force constant (at mid stroke) (N/A) |

back EMF- constant (at mid stroke) (V/m/s) |

coil resistance (at 25°C) (Ohm) |

inductance (mH) |

max. terminal voltage (V) |

coil mass (g) |

magnet mass (g) |

| CVC16-SF-5 | 5 | 4.04 | 0.71 | 5.06 | 0.892 | 0.80 | 0.80 | 1.7 | 0.14 | 48 | 5 | 10 |

| CVC19-SF-6 | 6.4 | 5.90 | 1.03 | 4.54 | 0.793 | 1.3 | 1.3 | 2.83 | 0.29 | 48 | 5 | 23 |

| CVC20-SF-10 | 10 | 8.21 | 1.43 | 4.28 | 0.746 | 1.92 | 1.92 | 3.67 | 0.44 | 48 | 10 | 32 |

| CVC24-SF-12 | 11 | 13.52 | 2.39 | 4.25 | 0.750 | 3.18 | 3.18 | 4.77 | 1.2 | 48 | 18 | 45 |

| CVC26-SF-7 | 7 | 17.11 | 3.01 | 2.90 | 0.510 | 5.9 | 5.9 | 11.16 | 2.95 | 48 | 16 | 53 |

| CVC30-SF-15 | 15 | 22.66 | 3.97 | 3.13 | 0.548 | 7.24 | 7.24 | 11.26 | 2.38 | 48 | 25 | 100 |

| CVC30-SF-30 | 30 | 16.24 | 5.13 | 3.96 | 1.25 | 4.10 | 4.10 | 6.70 | TBD | 48 | 45 | 198 |

| CVC35-HF-8 | 8 | 144.00 | 25.20 | 4.00 | 0.700 | 36.00 | 36.00 | 19.50 | 8.24 | 48 | 110 | 390 |

| CVC38-SF-10 | 10 | 42.09 | 7.32 | 3.76 | 0.653 | 11.21 | 11.21 | 10.35 | 3.47 | 48 | 45 | 168 |

| CVC40-SF-5 | 5 | 34.09 | 5.92 | 4.41 | 0.766 | 7.73 | 7.73 | 5.15 | 1.44 | 48 | 23 | 78 |

| CVC40-HF-6.5 | 6.5 | 92.42 | 16.09 | 3.59 | 0.642 | 25.78 | 25.78 | 16.03 | 5.52 | 48 | 75 | 255 |

| CVC40-HF-12 | 12 | 75.30 | 12.80 | 3.00 | 0.51 | 25.1 | 25.1 | 22.21 | TBD | 96 | 85 | 320 |

| CVC40-SF-20 | 20 | 47.92 | 8.34 | 3.13 | 0.545 | 15.31 | 15.31 | 17.50 | 5.59 | 48 | 60 | 230 |

| CVC44-SF-13 | 13 | 54.32 | 9.41 | 5.60 | 0.970 | 9.70 | 9.70 | 6.00 | 1.25 | 48 | 40 | 300 |

| CVC50-SF-30 | 30 | 74.91 | 13.14 | 4.23 | 0.742 | 17.71 | 17.71 | 15.19 | 4.14 | 48 | 100 | 526 |

| CVC60-SF-25 | 25 | 120.33 | 20.90 | 5.85 | 1.016 | 20.57 | 20.57 | 9.65 | 3.26 | 48 | 20 | 668 |

| CVC60-HF-20 | 20 | 218.50 | 37.72 | 4.75 | 0.820 | 46.00 | 46.00 | 24.00 | 15.40 | 120 | 410 | 1140 |

| CVC90-HF-20 | 20 | 640.74 | 111.41 | 15.77 | 2.742 | 40.63 | 40.63 | 3.45 | 4.88 | 120 | 1190 | 2425 |

|

|||||||||||||||||

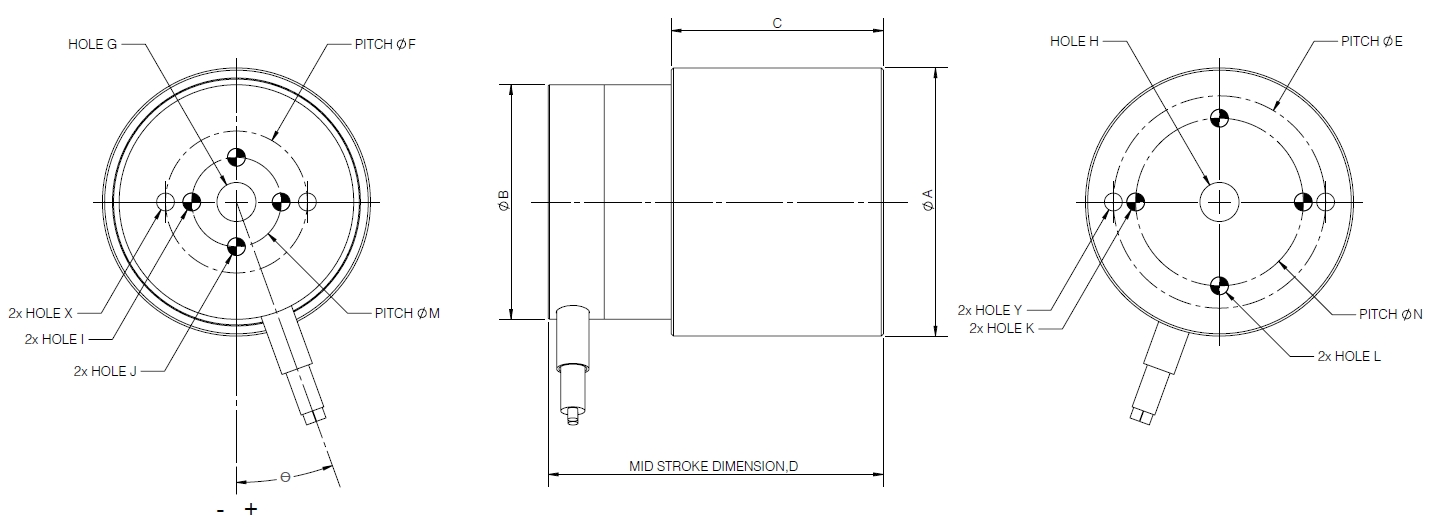

| dimensions Voice Coils CVC-series |

A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | G(mm) | H(mm) | I(mm) | J(mm) | K(mm) | L(mm) | M(mm) | N(mm) | X | Y | Φ |

| CVC16-SF-5 | 16.0 | 13.4 | 10.8 | 16.5 | 7.0 | 7.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M2.5 | M2.5 | 10° |

| CVC19-SF-6 | 19.0 | 15.7 | 15.8 | 24.0 | 9.0 | 9.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M3 | M3 | 25° |

| CVC20-SF-10 | 20.0 | 16.6 | 19.0 | 31.0 | 10.0 | 10.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M3 | M3 | 20° |

| CVC24-SF-12 | 24.0 | 21.0 | 19.0 | 30.0 | 19.0 | 12.7 | ⌀3.5(H7) | ⌀1.6 | N/A | N/A | N/A | N/A | N/A | N/A | M2 | M2 | 20° |

| CVC26-SF-7 | 26.0 | 22.0 | 20.0 | 27.5 | 12.0 | 12.0 | M3 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M2;M2.5;M3 | M3 | 20° |

| CVC30-SF-15 | 30.0 | 24.6 | 24.5 | 39.0 | 16.0 | 12.6 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M3 | M3 | 20° |

| CVC30-SF-30 | 30.0 | 25 | 43 | 64.8 | 21 | 14 | ⌀3.0(H7) | ⌀3.0 | N/A | N/A | N/A | N/A | N/A | N/A | M3 | M3 | 30° |

| CVC35-HF-8 | 35.0 | 30.4 | 80.8 | 92.5 | 27.0 | 12.6 | ⌀3.0(H7) | N/A | N/A | N/A | N/A | ⌀3.0(H7) | N/A | 27 | M3 | M3 | -25° |

| CVC38-SF-10 | 38.0 | 31.2 | 27.5 | 39.0 | 20.0 | 10.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M4 | M4 | 20° |

| CVC40-SF-5 | 40.0 | 34.0 | 12.0 | 17.5 | 20.0 | 20.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M4 | M4 | 20° |

| CVC40-HF-6.5 | 40.0 | 34.8 | 40.5 | 49.3 | 20.0 | 20.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M4 | M4 | -25° |

| CVC40-HF-12 | 40.0 | 33.2 | 44.7 | 55 | 20.0 | 20.0 | ⌀4.0(H7) | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M3 | M3 | 20° |

| CVC40-SF-20 | 40.0 | 33.2 | 32.5 | 49.8 | 20.0 | 20.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M4 | M4 | 20° |

| CVC44-SF-13 | 44.0 | 37.2 | 31.8 | 44.5 | 25.4 | 19.1 | ⌀6.5(H7) | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M4 | M4 | 20° |

| CVC50-SF-30 | 50.0 | 42.4 | 43.0 | 67.6 | 20.0 | 20.0 | ⌀4.0(H7) | ⌀4.0 | N/A | N/A | N/A | N/A | N/A | N/A | M4 | M4 | 30° |

| CVC60-SF-25 | 60.0 | 50.6 | 43.5 | 66.1 | 30.0 | 30.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | M5 | M5 | 20° |

| CVC60-HF-20 | 60.0 | 52.0 | 90.0 | 118.0 | 44.0 | 44.0 | ⌀8.0(H7) | ⌀8.0( | ⌀3.0(H7) | N/A | ⌀3.0(H7) | N/A | 32 | 32 | M5 | M5 | 20° |

| CVC90-HF-20 | 90.0 | 81.6 | 90.0 | 109.4 | 48.0 | 48.0 | ⌀12.0(H7) | ⌀12.0 | N/A | ⌀4.0(H7) | N/A | ⌀4.0(H7) | 40 | 34 | M6 | M6 | 35° |

VOICE COIL ACTUATORS WITH LINEAR GUIDE AND ENCODER (CVCA)

The Voice-Coil-Actuators of the CVCA-series use the Voice-Coil-Motors CVC and integrate those into a mechanical system including a cross roller bearing for low friciton and high precision and an optical encoder. Basically they are small linear motor tables or linear motor axis for short stroke and high dynamic response; they are very robust and reliable and are suited for applications in semiconductor or optical industries.

Our Accelnet servo amplifiers with DC supply and encoder feedback are suitable as servo controllers for the CVCA flat voice coil actuators.

- cross roller bearing for high precision and stiffness

- no cogging force

- low moving mass, fast dynamic response

- incremental encoder with resolution down to 100nm integrated

- high reliability and life

FLAT VOICE COIL ACTUATORS WITH LINEAR GUIDE AND ENCODER (RVCA)

The rectangular Voice-Coil-Actuators of the RVCA-series are the integration of a flat Voice-Coil-Motor into a mechanical system including a low friction cross roller bearing and an optical encoder. As the CVCA series they are small linear motor tables or linear motor axis for short stroke and high dynamic response; they are very robust and reliable. Their rectangular profile with one dimension being very flat, makes them ideally suited for applications with space constraints; the integrated return spring compensates for gravity force in vertical z-axis linear motor stage. Applications can be found in high speed assembly applications e.g. in semiconductor industry or in optical industriy.

Our Accelnet servo amplifiers with DC supply and encoder feedback are suitable as servo controllers for the RVCA flat voice coil actuators.

- ideally suited for high speed pick&place applications

- cross roller bearing for high precision and stiffness

- no cogging force

- low moving mass, fast dynamic response

- return spring integrated, e.g. to compensate for gravity in z-axis (vertical)

- incremental encoder with resolution down to 100nm integrated

- high precision, reliability and life

- plug&play integration

PDF Voice Coil Actuators Overview

PDF Voice Coil Actuators Overview

PRINT PAGE |

PRINT PAGE |