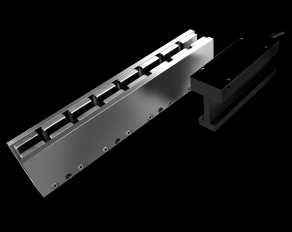

DX: IRONLESS LINEAR MOTORS WITH ZERO COGGING

Our partner PBA has been established on the market as a linear motor manufacturer for almost 20 years. Innovative strength, quality and technical support and service are the guiding principles of our partner. Our linear motors offer high force density, high rigidity and do not require any maintenance.

The DX motors are ironless linear motors, which are ideally suited for applications with extreme synchronization requirements due to their cogging-free behavior. Applications for these miniature linear motors are found in microscopes, optical applications (scanners), semiconductor technology and micro-mounting. The ironless linear motor modules of the DX series are characterized by their compact design and the very good price-performance ratio.

The most important features of the DX ironless linear motors are:

- optimized design for best performance due to high motor constant

- high acceleration values

- perfect and smooth moving also at low speed due to zero detent force (zero cogging)

- no magnetic attraction

- several sizes with coil assemblies and magnetic tracks in several lengths

- peak forces from 16N to 5,366N (up to 8,787N with new DX-F series)

- continuous forces from 3N to 1,023N (up to 1,757N with new DX-F series)

- very good price/performance ratio

| model | continuous force N |

peak force N |

continuous current Arms |

peak current Apk |

max. voltage Vdc |

motor constant N/W^1/2 |

coil mass kg |

coil length mm |

3D-models step (in .zip) |

||

| S | P | S | P | ||||||||

| DX20F-C1 | 10 | 49 | 1.50 | - | 11.25 | - | 330 | 3.23 | 0.06 | 31 |

DX20F models |

| DX20F-C2 | 20 | 98 | 1.38 | 2.76 | 11.27 | 22.54 | 3.23 | 0.12 | 61 | ||

| DX20F-C3 | 29 | 147 | 3.95 | 0.18 | 91 | ||||||

| DX20F-C4 | 39 | 196 | 4.56 | 0.27 | 121 | ||||||

| DX20F-C5 | 49 | 245 | 5.10 | 0.36 | 151 | ||||||

| DX30F-C1 | 35 | 174 | 1.73 | 3.46 | 14.13 | 28.25 | 330 | 5.95 | 0.22 | 61 |

DX30F models |

| DX30F-C2 | 69 | 347 | 8.42 | 0.47 | 121 | ||||||

| DX30F-C3 | 104 | 521 | 10.31 | 0.65 | 181 | ||||||

| DX30F-C4 | 139 | 695 | 11.91 | 0.89 | 241 | ||||||

| DX30F-C5 | 174 | 869 | 13.31 | 1.10 | 301 | ||||||

| DX50F-C1 | 64 | 319 | 1.73 | - | 14.13 | - | 330 | 9.10 | 0.28 | 61 |

DX50F models |

| DX50F-C2 | 128 | 638 | - | 3.46 | - | 28.25 | 12.86 | 0.56 | 121 | ||

| DX50F-C3 | 192 | 958 | - | 3.46 | - | 28.25 | 15.76 | 0.84 | 181 | ||

| DX50F-C4 | 255 | 1277 | - | 3.46 | - | 28.25 | 18.19 | 1.12 | 241 | ||

| DX50FT-C4 | 255 | 1277 | - | 6.92 | - | 56.50 | 18.19 | 1.12 | 241 | ||

| DX50FT-C6 | 383 | 1915 | - | 6.92 | - | 56.50 | 22.28 | 1.68 | 361 | ||

| DX65F-C1 | 75 | 531 | 2.90 | - | 33.6 | - | 330 | 11.7 | 0.57 | 85 |

DX65F models |

| DX65F-C2 | 150 | 1062 | 2.90 | - | 33.60 | - | 16.6 | 1.14 | 145 | ||

| DX65F-C3 | 224 | 1594 | 2.90 | - | 33.60 | - | 20.3 | 1.17 | 205 | ||

| DX65F-C4 | 299 | 2125 | - | 5.80 | - | 67.2 | 23.5 | 2.28 | 265 | ||

| DX65FT-C5 | 374 | 2656 | - | 9.67 | - | 97.0 | 26.3 | 2.85 | 325 | ||

| DX65F-C6 | 449 | 3187 | - | 5.80 | - | 67.2 | 28.8 | 3.42 | 385 | ||

| DX65F-C8 | 599 | 4249 | - | 5.80 | - | 67.2 | 33.2 | 4.56 | 505 | ||

| DX65FT-C10 | 748 | 5312 | - | 9.67 | - | 97.0 | 37.1 | 5.70 | 625 | ||

| DX65F-C12 | 898 | 6374 | - | 8.70 | - | 100.9 | 40.7 | 6.84 | 745 | ||

| DX140F-C1 | 176 | 879 | 2.28 | - | 16.12 | - | 330 | 20.53 | 0.80 | 85 |

DX140F models |

| DX140F-C2 | 351 | 1757 | - | 4.56 | - | 32.34 | 29.03 | 1.52 | 145 | ||

| DX140F-C3 | 527 | 2636 | - | 6.84 | - | 48.37 | 35.55 | 2.50 | 205 | ||

| DX140F-C4 | 703 | 3515 | - | 9.12 | - | 64.49 | 41.05 | 3.40 | 265 | ||

| DX140F-C6 | 1054 | 5272 | - | 13.68 | - | 96.73 | 50.28 | 5.00 | 385 | ||

| DX140F-C8 | 1406 | 7029 | - | 9.12 | - | 64.49 | 58.06 | 6.70 | 505 | ||

| DX140F-C10 | 1757 | 8787 | - | 11.40 | - | 80.61 | 64.91 | 8.40 | 625 | ||

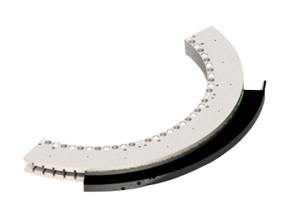

ARC: CURVED IRONLESS LINEAR MOTORS WITHOUT COGGING FORCE AS CIRCLE SEGMENT

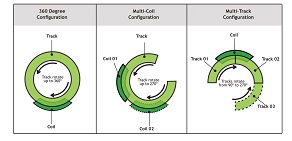

The latest innovation of our partner PBA Systems are curved linear motors based on the ironless linear motors of the DX series. Both the coils and the magnetic tracks of the ARC series are designed as circular segments; the magnetic tracks can be extended to full circle. This allows the realization of applications that only require motion in a limited angular segment, or applications for the full 360° (or multiturn) with a large hollow shaft up to 1504mm! Also the ARC series are direct drives in extremely flat design and are suitable for rotary tables in industry and machine building and offer high force density, high stiffness and need no maintenance.

The ARC motors are curved or bent ironless linear motors, designed as an arc segment, without cogging force. Due to their cogging-free behavior, they are best suited for applications with extreme synchronization requirements. When installed in the application, arc or angular contact ball bearings and a good encoder system are required to ensure high precision and repeatability. ARC direct drives are found in semiconductor machines, wafer production and wafer inspection machines, photonics and laser technology, biomedical equipment, lithium battery production equipment and printing equipment. The achievable large bore or hollow shaft and the assembly from partial segments often has advantages over a rotor as a solid shaft.

- Motor components consisting a forcer and a magnetic path as an arc segment

- several arc segments of the magnetic path can be combined up to a full circle

- several forcers possible to increase the force (or torque)

- best performance due to high motor constant

- high acceleration values

- perfect running due to zero cogging force

- no magnetic attraction

- 3 sizes with magnetic tracks in several angular segments

- peak torque from 91.5Nm to 1,031.8Nm

- continuous torque from 18.3Nm to 343.9Nm

- very good price/performance ratio

| model | continuous force N |

peak force N |

continuous current Arms |

peak current Apk |

max. voltage Vdc |

motor constant N/W^1/2 |

coil mass kg |

coil angle ° |

magnetic tracks angle segments |

3D-models step (in .zip) |

| ARC170-S-C5 | 18.3 | 91.5 | 1.67 | 11.84 | 330 | 1.6 | 0.85 | 90.4 | ARCM170-TA036 -36° ARCM170-TA054 -54° |

models ARC170 |

| ARC280-S-C5 | 95.5 | 280.5 | 1.63 | 6.91 | 400 | 5.5 | 1.5 | 90.4 | ARCM280-TA036 -36° ARCM280-TA054 -54° |

moedels ARC280 |

| ARC750-S-C5 | 343.9 | 1,031.8 | 2.25 | 9.55 | 600 | 31.5 | 2.3 | 40.4 | ARCM750-TA024 -24° ARCM750-TA028 -28° |

models ARC750 |

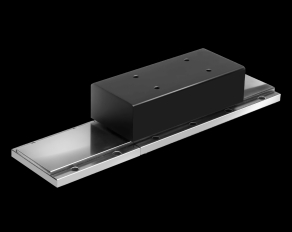

PIXB: HIGH FORCE IRON-CORE LINEAR MOTORS WITH LOW COGGING

The PIXB linear motors from PBA are iron-core linear motors designed for point-to-point applications with high speed and tough requirements. The PIXB direct drive linear motors offer a very high force density and high rigidity with a comparatively minimal magnetic attraction and cogging force and require no maintenance.

The PIXB linear motors are optimised for good heat dissipation and can therefore offer very high forces of up to 3,200N in the existing installation space. The coil assemblies are equipped with highly flexible cables and hall effect sensors can be fitted as an option. The PIXB linear motors are used in many automation technology applications that require high force.

The most important features of PIXB iron-core linear motors are:

- optimized thermal design for high force

- minimal magnetic attraction and cogging force

- several sizes with coil assemblies and magnetic tracks in several lengths

- peak force from 121N to 3,200N

- continuous force from 35N to 1,463N

| model | continuous force N |

peak force N |

continuous current Arms |

peak current Apk |

max. voltage Vdc |

motor constant N/W^1/2 |

coil mass kg |

coil length mm |

attraction force N |

3D-models step (in .zip) |

| PIXB150B-050-C1 | 35 | 121 | 3.3 | 12.7 | 600 | 8.1 | 0.35 | 58 | 210 | PIX150B models |

| PIXB150B-050-C2 | 69 | 242 | 3.3 | 12.7 | 600 | 11.5 | 0.6 | 100 | 420 | |

| PIXB150B-050-C3 | 104 | 363 | 3.3 | 12.7 | 600 | 14.1 | 0.9 | 142 | 630 | |

| PIXB150B-050-C4 | 139 | 484 | 6.5 | 25.4 | 600 | 16.3 | 1.1 | 184 | 840 | |

| PIXB150B-075-C1 | 59 | 208 | 3.3 | 12.7 | 600 | 11.5 | 0.5 | 58 | 360 | |

| PIXB150B-075-C2 | 119 | 416 | 3.3 | 12.7 | 600 | 16.3 | 0.9 | 100 | 720 | |

| PIXB150B-075-C3 | 178 | 624 | 3.3 | 12.7 | 600 | 20.0 | 1.3 | 142 | 1080 | |

| PIXB150B-075-C4 | 238 | 832 | 6.5 | 25.4 | 600 | 23.1 | 1.6 | 184 | 1440 | |

| PIXB150B-100-C1 | 89 | 310 | 3.3 | 12.7 | 600 | 14.7 | 0.7 | 58 | 540 | |

| PIXB150B-100-C2 | 177 | 620 | 3.3 | 12.7 | 600 | 20.8 | 1.2 | 100 | 1080 | |

| PIXB150B-100-C3 | 266 | 930 | 3.3 | 12.7 | 600 | 25.4 | 1.8 | 142 | 1620 | |

| PIXB150B-100-C4 | 355 | 1240 | 6.5 | 25.4 | 600 | 29.4 | 2.3 | 184 | 2160 | |

| PIXB150B-125-C1 | 114 | 397 | 3.3 | 12.7 | 600 | 16.3 | 0.85 | 58 | 690 | |

| PIXB150B-125-C2 | 227 | 794 | 3.3 | 12.7 | 600 | 23.0 | 1.5 | 100 | 1380 | |

| PIXB150B-125-C3 | 341 | 1191 | 3.3 | 12.7 | 600 | 28.1 | 2.1 | 142 | 2070 | |

| PIXB150B-125-C4 | 454 | 1588 | 6.5 | 25.4 | 600 | 32.5 | 2.8 | 184 | 2760 | |

| PIXB250B-050-C1 | 110 | 240 | 6.8 | 20.4 | 600 | 18.7 | 1.3 | 105 | 500 | PIX250B models |

| PIXB250B-050-C2 | 220 | 480 | 6.8 | 20.4 | 600 | 26.4 | 2.3 | 189 | 1000 | |

| PIXB250B-050-C3 | 330 | 720 | 6.8 | 20.4 | 600 | 32.4 | 3.4 | 273 | 1500 | |

| PIXB250B-050-C4 | 440 | 960 | 13.6 | 40.8 | 600 | 37.4 | 4.4 | 357 | 2000 | |

| PIXB250B-075-C1 | 183 | 400 | 6.8 | 20.4 | 600 | 26.7 | 2.1 | 105 | 820 | |

| PIXB250B-075-C2 | 366 | 800 | 6.8 | 20.4 | 600 | 37.7 | 4.0 | 189 | 1640 | |

| PIXB250B-075-C3 | 549 | 1200 | 6.8 | 20.4 | 600 | 46.2 | 5.9 | 273 | 2460 | |

| PIXB250B-075-C4 | 733 | 1600 | 13.6 | 40.8 | 600 | 53.3 | 7.8 | 357 | 3280 | |

| PIXB250B-100-C1 | 274 | 600 | 6.8 | 20.4 | 600 | 34.7 | 2.7 | 105 | 1240 | |

| PIXB250B-100-C2 | 548 | 1200 | 6.8 | 20.4 | 600 | 49.0 | 4.8 | 189 | 2480 | |

| PIXB250B-100-C3 | 823 | 1800 | 6.8 | 20.4 | 600 | 60.1 | 6.9 | 273 | 3720 | |

| PIXB250B-100-C4 | 1097 | 2400 | 13.6 | 40.8 | 600 | 69.3 | 9.0 | 357 | 4960 | |

| PIXB250B-125-C1 | 336 | 800 | 6.8 | 20.4 | 600 | 41.9 | 3.9 | 105 | 1650 | |

| PIXB250B-125-C2 | 731 | 1600 | 6.8 | 20.4 | 600 | 59.3 | 7.3 | 189 | 3300 | |

| PIXB250B-125-C3 | 1097 | 2400 | 6.8 | 20.4 | 600 | 72.6 | 10.7 | 273 | 4950 | |

| PIXB250B-125-C4 | 1463 | 3200 | 13.6 | 40.8 | 600 | 83.9 | 14.0 | 357 | 6600 | |

| PIXB350B-180-C4 | 2052 | 4800 | 12.7 | 40.8 | 600 | 94.4 | 17.6 | 357 | 9920 | PIX350B models |

| PIXB350B-180-C6 | 3078 | 7200 | 19.1 | 61.1 | 600 | 115.6 | 25.9 | 525 | 14880 | |

| PIXB350B-180-C8 | 4104 | 9600 | 25.5 | 81.5 | 600 | 152.4 | 34.2 | 693 | 19840 | |

| PIXB350B-250-C4 | 2736 | 6400 | 12.7 | 40.8 | 600 | 125.6 | 24.4 | 357 | 13200 | |

| PIXB350B-250-C6 | 4101 | 9600 | 19.1 | 61.1 | 600 | 153.8 | 35.9 | 525 | 39600 | |

| PIXB350B-250-C8 | 5471 | 12800 | 25.5 | 81.5 | 600 | 177.6 | 47.4 | 693 | 26400 |

| model | continuous force N |

peak force N |

continuous current Arms |

peak current Apk |

max. voltage Vdc |

motor constant N/W^1/2 |

coil mass kg |

coil length mm |

3D-models step (in.zip) |

||

| S | P | S | P | ||||||||

| PIX200-027-030 | 108 | 542 | 6.1 | 12.2 | 30.4 | 60.8 | 14.9 | 1.3 | 54 | 1560 | PIX200 models |

| PIX200-027-050 | 179 | 893 | 5.9 | 11.7 | 29.3 | 58.7 | 21.8 | 2.0 | 74 | 2600 | |

| PIX200-027-080 | 279 | 1393 | 5.6 | 11.1 | 27.9 | 55.7 | 30.3 | 3.1 | 104 | 4160 | |

| PIX200-040-030 | 189 | 943 | 4.4 | 8.8 | 21.9 | 43.8 | 24.0 | 2.1 | 54 | 1560 | |

| PIX200-040-050 | 303 | 1515 | 4.1 | 8.2 | 20.5 | 41.0 | 34.6 | 3.1 | 74 | 2600 | |

| PIX200-040-080 | 461 | 2307 | 4.0 | 7.9 | 19.8 | 39.6 | 46.1 | 4.6 | 104 | 4160 | |

PDF PBA DX-F Linear Motors Catalogue

PDF PBA DX-F Linear Motors Catalogue

PRINT PAGE |

PRINT PAGE |